Chemical Science and Engineering News

Fostering creativity in researchers: How Automation Can Revolutionize Materials Research

Scientists at Tokyo Institute of Technology (Tokyo Tech) devise a system that combines robotics and artificial intelligence to fully automate the routine aspects of synthesizing, testing, and optimizing new materials according to fabrication conditions. Their approach can produce and test compounds ten times faster than scientists doing manual work, allowing for the rapid creation of huge shared databases. In turn, the autonomous system and database will be used to discover exotic material properties and new laws of physics.

At the heart of many past scientific breakthroughs lies the discovery of novel materials. However, the cycle of synthesizing, testing, and optimizing new materials routinely takes scientists long hours of hard work. Because of this, lots of potentially useful materials with exotic properties remain undiscovered. But what if we could automate the entire novel material development process using robotics and artificial intelligence, making it much faster?

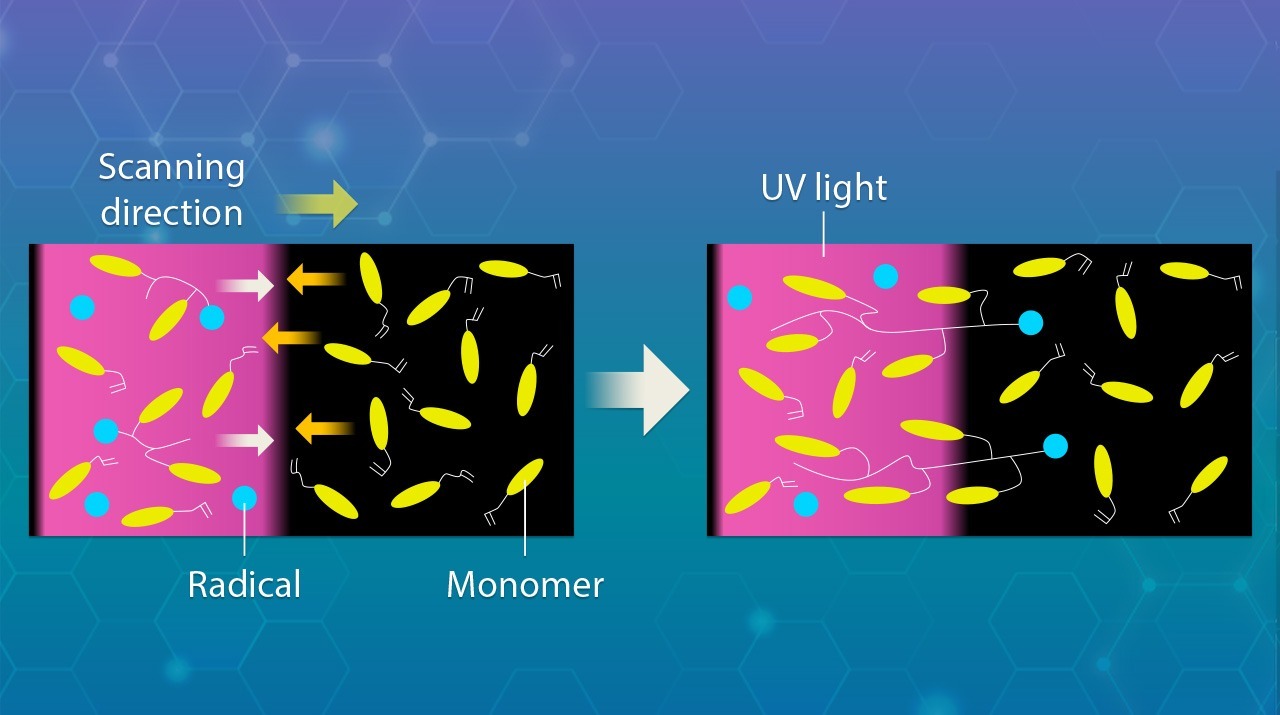

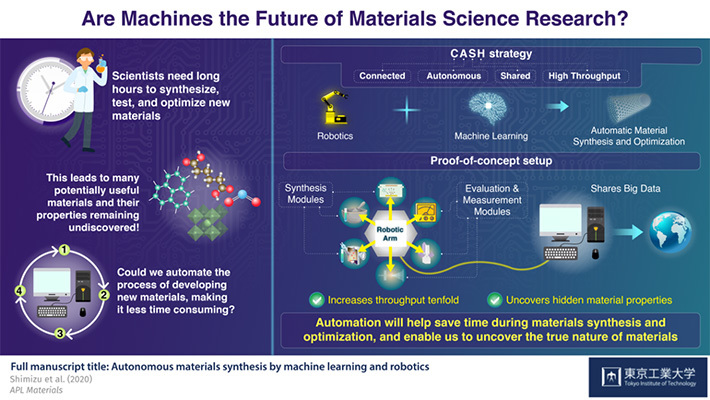

In a recent study published at APL Material, scientists from Tokyo Institute of Technology (Tokyo Tech), Japan, led by Associate Professor Ryota Shimizu and Professor Taro Hitosugi, devised a strategy that could make fully autonomous materials research a reality. Their work is centered around the revolutionary idea of laboratory equipment being ‘CASH’ (Connected, Autonomous, Shared, High-throughput). With a CASH setup in a materials laboratory, researchers need only decide which material properties they want to optimize and feed the system the necessary ingredients; the automatic system then takes control and repeatedly prepares and tests new compounds until the best one is found. Using machine learning algorithms, the system can employ previous knowledge to decide how synthesis conditions should be changed to approach the desired outcome in each cycle.

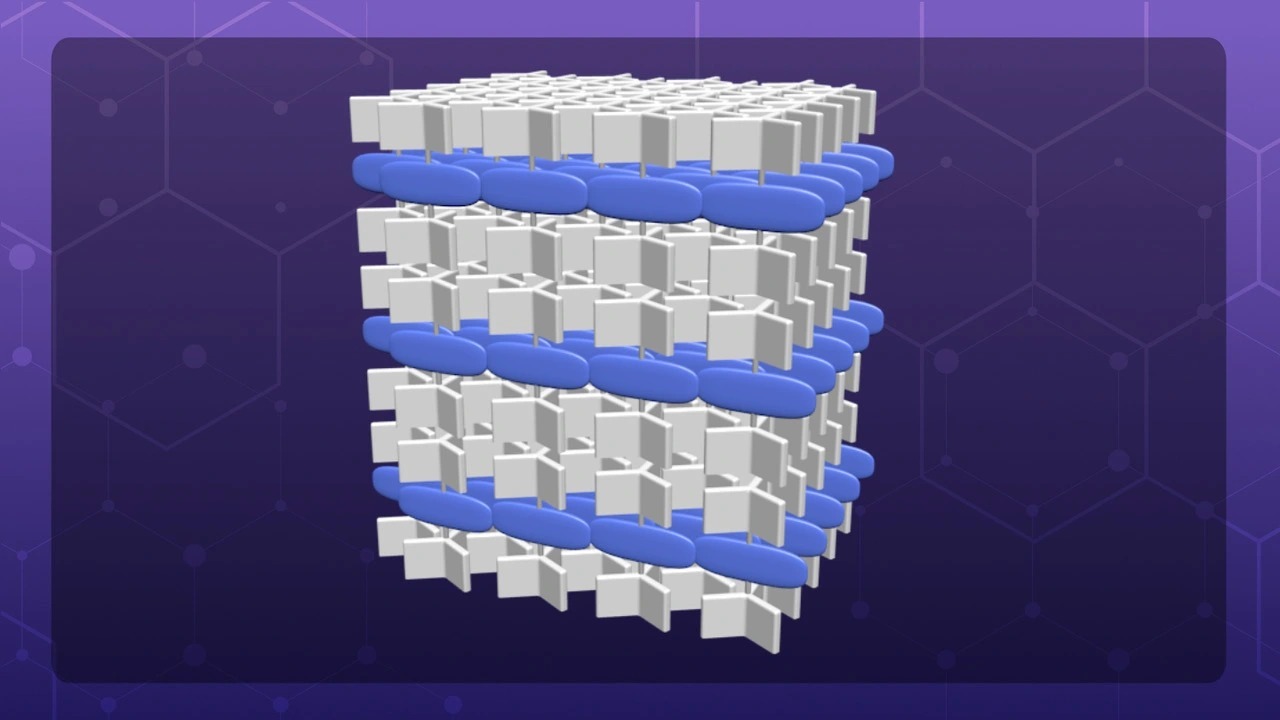

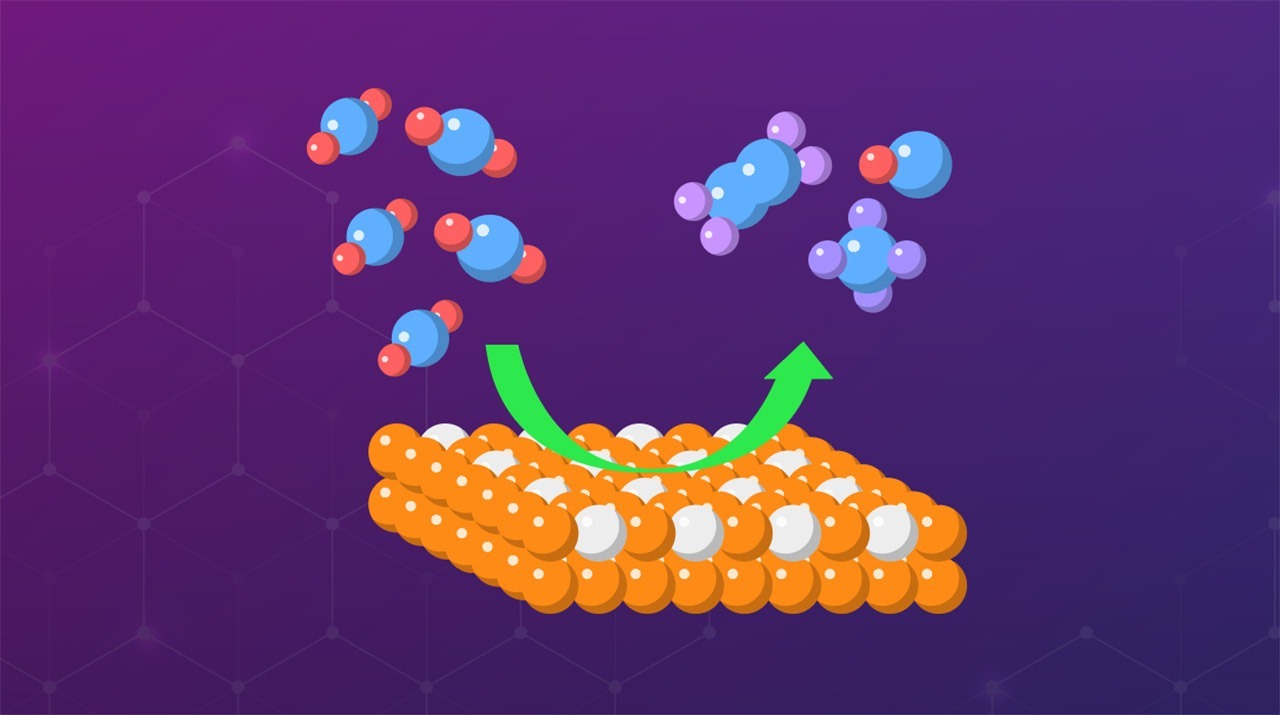

To demonstrate that CASH is a feasible strategy in solid-state materials research, Associate Prof Shimizu and team created a proof-of-concept system comprising a robotic arm surrounded by several modules. Their setup was geared toward minimizing the electrical resistance of a titanium dioxide thin film by adjusting the deposition conditions. Therefore, the modules are a sputter deposition apparatus and a device for measuring resistance. The robotic arm transferred the samples from module to module as needed, and the system autonomously predicted the synthesis parameters for the next iteration based on previous data. For the prediction, they used the Bayesian optimization algorithm.

Amazingly, their CASH setup managed to produce and test about twelve samples per day, a tenfold increase in throughput compared to what scientists can manually achieve in a conventional laboratory. In addition to this significant increase in speed, one of the main advantages of the CASH strategy is the possibility of creating huge shared databases describing how material properties vary according to synthesis conditions. In this regard, Prof Hitosugi remarks: “Today, databases of substances and their properties remain incomplete. With the CASH approach, we could easily complete them and then discover hidden material properties, leading to the discovery of new laws of physics and resulting in insights through statistical analysis.”

The research team believes that the CASH approach will bring about a revolution in materials science. Databases generated quickly and effortlessly by CASH systems will be combined into big data and scientists will use advanced algorithms to process them and extract human-understandable expressions. However, as Prof Hitosugi notes, machine learning and robotics alone cannot find insights nor discover concepts in physics and chemistry. “The training of future materials scientists must evolve; they will need to understand what machine learning can solve and set the problem accordingly. The strength of human researchers lies in creating concepts or identifying problems in society. Combining those strengths with machine learning and robotics is very important,” he says.

Overall, this perspective article highlights the tremendous benefits that automation could bring to materials science. If the weight of repetitive tasks is lifted off the shoulders of researchers, they will be able to focus more on uncovering the secrets of the material world for the benefit of humanity.

- Reference

| Authors : | Ryota Shimizu1,2*, Shigeru Kobayashi1, Yuki Watanabe1, Yasunobu Ando3*, and Taro Hitosugi1* |

|---|---|

| Title of original paper : | Autonomous materials synthesis by machine learning and robotics |

| Journal : | APL Materials |

| DOI : | 10.1063/5.0020370 |

| Affiliations : |

1 School of Materials and Chemical Technology, Tokyo Institute of Technology 2 PRESTO, Japan Science and Technology Agency 3 Research Center for Computational Design of Advanced Functional Materials, National Institute of Advanced Industrial Science and Technology |

* Corresponding author's emails: shimizu.r.af@m.titech.ac.jp (R. S.), yasunobu.ando@aist.go.jp (Y. A.), hitosugi.t.aa@m.titech.ac.jp (T. H.)

- Making it crystal clear: Crystallinity reduces resistance in all-solid-state batteries | Tokyo Tech News

- Expanding the limits of Li-ion batteries: Interface for all-solid-state batteries | Tokyo Tech News

- Toward the next generation of superconductors and lithium-ion batteries: Scanning the surface of lithium titanate | Tokyo Tech News

- Learning how to fine-tune nanofabrication | Tokyo Tech News

- Atom engineering: From all-solid-state batteries to room temperature superconductivity | Taking your first step as a researcher | Prospective Students

- 2018 Tokyo Tech Challenging Research Award | Tokyo Tech News

- Hitosugi Laboratory

- Researcher Profile | Tokyo Tech STAR Search - Taro Hitosugi

- Researcher Profile | Tokyo Tech STAR Search - Ryota Shimizu

- Chemical Science and Engineering Graduate Major|Educaton|Department of Chemical Science and Engineering, School of Materials and Chemical Technology

- Energy Science and Engineering Graduate Major|Educaton|Department of Chemical Science and Engineering, School of Materials and Chemical Technology

- Research Center for Computational Design of Advanced Functional Materials | National Institute of Advanced Industrial Science and Technology

- Latest Research News

School of Materials and Chemical Technology

—Encompassing the Disciplines of Science—

Information on School of Materials and Chemical Technology inaugurated in April 2016

Further Information

Associate Professor Ryota Shimizu

School of Materials and Chemical Technology,

Tokyo Institute of Technology